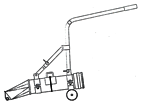

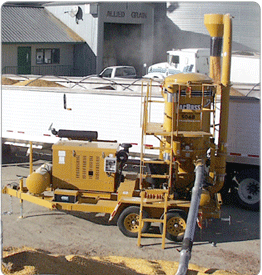

Move up to 5,800 bu/hr** with a VacBoss Pneumatic Conveyor!

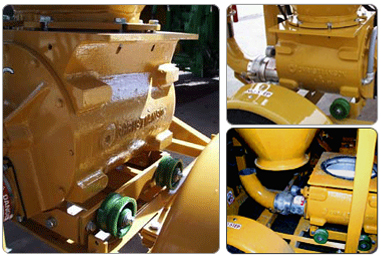

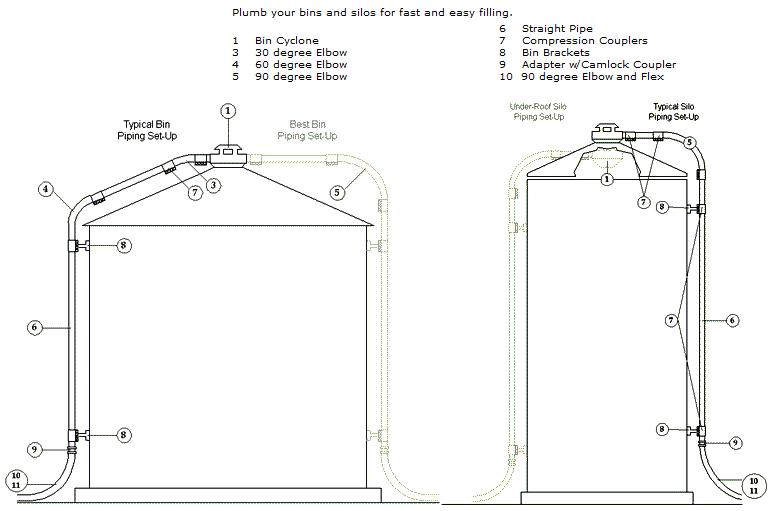

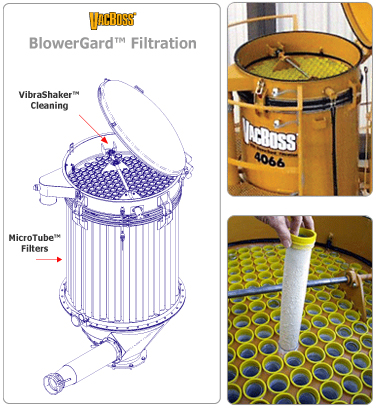

The VacBoss is the best choice for commercial or high volume operators. The state-of-the-art technology will raise the standards when comparing quality, construction and performance to the traditional vac. The VacBoss is the only vac to offer an abrasion-free blower warranty. The heavy-duty design will protect your investment over time providing a machine that will last longer and move more grain. Whether you run a large farm, bulk terminal, or provide transfer service, VacBoss delivers the flexibility and performance you need.

** Capacity is stated in bushels per hour, is approximate and depends on many variables – please refer to capacity charts for more detailed information.

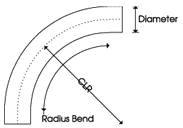

Reduces the incoming air velocity by up to 60%, decelerating the bulk material as it enters the receiving cone. Improves efficiency, reduces wear, and results in gentler bulk material handling.

Reduces the incoming air velocity by up to 60%, decelerating the bulk material as it enters the receiving cone. Improves efficiency, reduces wear, and results in gentler bulk material handling.