Push your grain on a cushion of air!

PUSH-PAC conveyors are compact, self contained pressure-only pneumatic systems designed to convey grain to silos and bins. Versatile, powerful, and easy to install, PUSH-PACs efficiently and gently “push” grain 100′ to 250′ (30m to 75m) or more.

Push-Pacs are ideal for transferring grain to or from dryers, trucks, dump pits, hoppers, storage bins, silos, mixers, bunkers, railcars and feed bins.

PUSH-PACs are portable enough to service several grain transfer sites. Convenient fork lift base and lifting loops make moving the PUSH-PAC system a simple operation.

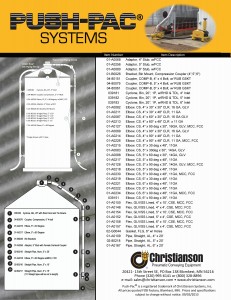

Choose from five basic PUSH-PAC models to meet your grain transfer needs:

| Specifications | Conveying Capabilities | ||||

| Model 30 | 10 HP | 1 or 3 Phase | 3″ | 300-500 Bu/Hr | 8.0-13.6 mt/Hr |

| Model 40 | 15 HP | 3 Phase | 4″ | 500-800 Bu/Hr | 13.6-21.8 mt/Hr |

| Model 50 | 30 HP | 3 Phase | 5″ | 900-1300 Bu/Hr | 24.5-35.4 mt/Hr |

| Model 60 | 50 HP | 3 Phase | 6″ | 1200-1900 Bu/Hr | 32.7-51.7 mt/Hr |

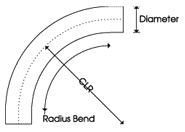

*Capacities shown using 100′ (30m) of piping – 70′ (21m) horizontal, 30′ (9m) vertical and two 90′ elbows – moving dry US #2 corn. Capacities will vary depending on distances, type and condition of grain, altitude, temperature, humidity and piping set-up. Long distance conveying at an incline should be avoided.

To minimize grain damage and pipe wear, use a surge bin or hopper to feed the PUSH-PAC when transferring grain from a dryer .

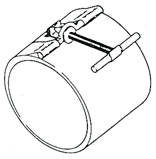

Remote Airlock Drive Option

This optional setup is available on all the PUSH-PAC models. The airlock unit is mounted on a separate frame with its own electric drive motor and reduction gearbox, enabling the air pump and main drive motor to be remotely located – convenient for restricted quarters or specialized applications