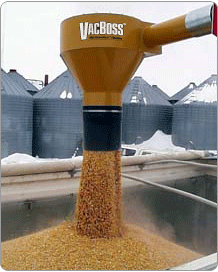

Big Volume requires big capacity.

There’s a VacBoss big enough to get the job done.

Capacities are approximate and vary depending upon altitude, ambient temperature, pipe setup and the type, condition, and moisture content of the grain. Conveying capacities are given in bushels per hour and (metric tons per hour).

VacBoss Model 4066 (PTO and Diesel)

| Hose Length | Oats | Barley | Corn | Wheat | Soybeans |

| 10 ft. (3.3m) | 3,800 – 4,300 (66 – 74) |

3,800 – 4,200 (86 – 95) |

3,900 – 4,000 (99 – 102) |

3,600 – 4,000 (95 – 105) |

3,400 – 3,800 (91 – 102) |

| 40 ft. (12.2m) | 3,800 – 4,200 (66 – 73) |

3,800 – 4,200 (86 – 95) |

3,650 – 3,850 ( 93 – 98) |

3,200 – 3,800 (84 – 100) |

3,000 – 3,600 (801 – 97) |

| 80 ft. (24.4m) | 3,500 – 4,000 (60 – 69) |

3,400 – 3,800 (77 – 86) |

3,200 – 3,600 ( 81 – 92) |

2,600 – 3,200 (68 – 84) |

2,400 – 3,000 (64 – 80) |

| 120 ft. (36.6m) | 3,000 – 3,800 (51 – 66) |

2,800 – 3,500 (67 – 80) |

2,100 – 2,500 (53 – 64) |

1,500 – 2,500 (40 – 66) |

1,300 – 2,300 (34 – 62) |

VacBoss Model 6068 (PTO and Diesel)

| Hose Length | Oats | Barley | Corn | Wheat | Soybeans |

| 10 ft. (3.3m) | 5,600 – 6,150 (66 – 73) |

5,100 – 5,900 (97 – 112) |

5,300 – 5,700 (135 – 145) |

5,000 – 6,000 (136 – 163) |

4,800 – 5,800 (131 – 158) |

| 20 ft. (6.6m) | 5,500 – 6,000 (65 – 71) |

5,000 – 5,800 95 – 110) |

5,100 – 5,600 (127 – 142) |

4,800 – 5,800 (131 – 158) |

4,600 – 5,600 (125 – 152) |

| 40 ft. (12.2m) | 5,100 – 5,600 (60 – 66) |

4,600 – 5,400 (88 – 103) |

4,750 – 5,350 (121 – 136) |

4,500 – 5,000 (122 – 136) |

4,300 – 4,800 (117 – 131) |

| 80 ft. (24.4m) | 4,600 – 5,100 (54 – 60) |

4,000 – 5,000 (76 – 95) |

4,000 – 5,000 (102 – 127) |

3,700 – 4,700 (101 – 128) |

3,500 – 4,500 (95 – 123) |

| 100 ft. (30m) | 4,100 – 4,600 (48 – 54) |

3,500 – 4,500 (67 – 86) |

3,500 – 4,500 (89 – 114) |

3,200 – 4,200 (87 – 114) |

3,000 – 4,000 (82 – 108) |

All capacities and specifications subject to change without notice.